Department Displays Science as Art Winners

Oct. 12, 2020 - The Department of Materials Science and Engineering and its Graduate Student Association launched the first ever Science as Art competition in Fall 2019, and the three winning artworks are now displayed on the fifth floor in Engineering Tower, in the hallway and the MSE department business office.

According to Amy Ricks, department manager, the annual competition aims to encourage students and researchers to highlight the beauty in their MSE research and share it with the UCI community on a level that everyone can appreciate. Entries featured optical, scanning electron and transmission electron microscopy or other microscopy or spectroscopy techniques with minimal modifications. The first, second and third place winners were selected from 25 entries submitted by undergraduate and graduate students, postdoctoral scholars and other researchers. All members of the department were invited to vote for the images they felt best translated as art.

Here are the winning entries, with explanations provided by the artists, who are all Ph.D. students in materials science and engineering.

First Place

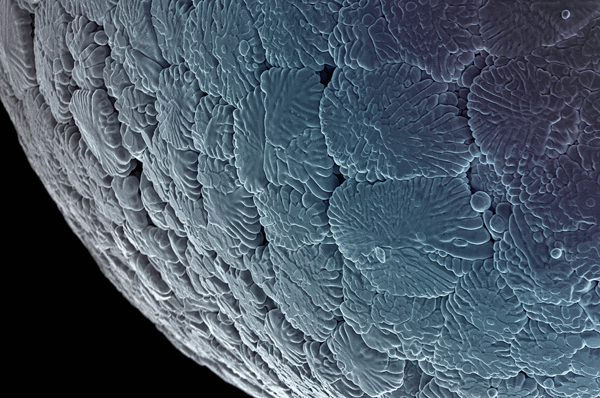

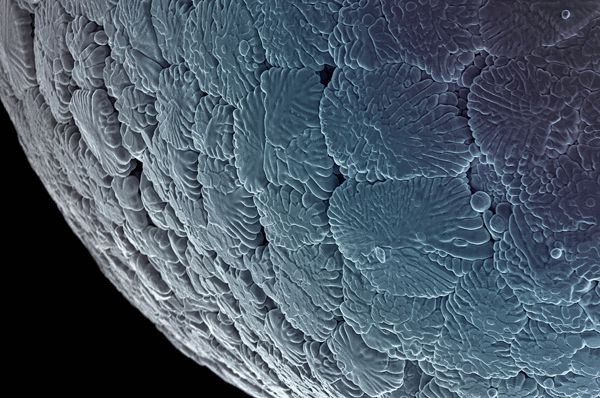

“Moon Landing”

Sasha Vyatskikh

This image shows a microscopic spherical metal particle that was made with a technique called gas atomization. These gas-atomized powders were then used for metal 3D printing, which has the potential to revolutionize the field of manufacturing. Many challenges still need to be overcome, however. We try to better understand why defects are developed in 3D printed metal parts and how to predict and avoid them.

Second Place

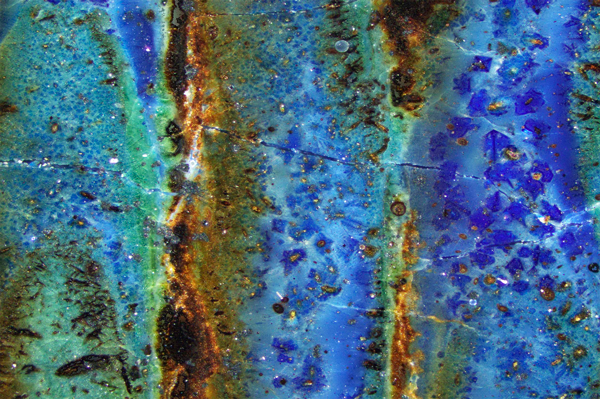

“3D Printed Galaxies”

Katherine Acord

3D printing technologies are being explored to improve battery life while decreasing the amount of time to recharge. This picture shows a lithium-ion battery cathode material that was fabricated using a laser-based 3D printing technique. The vibrant colors result from high temperatures and rapid cooling rates induced by the laser beam, which changes the internal chemical and electronic structure.

Third Place

“Ceramic Beach”

Yingjie Yang

The image was taken in an electron microscope and shows a ceramic composite that is processed by flash sintering. In the conventional ceramic industry, electricity is used to heat up a furnace and the furnace heats up the material. Energy takes up to 30% of the total production cost, and a large fraction comes from fossil fuels. We study ceramic manufacturing aiming to process materials with less energy and time, reducing the environmental effect and the manufacturing cost. We study the technique − flash sintering − and how it applies to ceramic materials. Flash sintering directly applies electricity to the sample, reducing the furnace temperature needed, hence reducing energy consumption. The two compounds in the material are alumina (darker stripes) and La-monazite (brighter stripes). Alumina has high hardness and is one of the most commonly used structural materials.

– Lori Brandt