A Revolutionary Wine Glass in a Gyroscope

UCI Samueli School of Engineering Associate Dean of Research and Innovation Andrei Shkel

Dec. 9, 2024 - During a stroll down a street in Barcelona’s Poble Espanyol, Andrei Shkel saw a man inflating molten glass with a blowpipe and shaping it into a perfect sphere. As a professor of mechanical and aerospace engineering, Shkel imagined an ingenious application for the ancient art: glassblowing could enable the world to make tiny “wine glasses” for small gyroscopes.

That epiphany skyrocketed his career, bringing him to the U.S. Department of Defense to head the mission to miniaturize gyroscopes - the key devices that measure rotation for navigation, positioning and stabilization. From 2009 to 2013 at the Defense Advanced Research Projects Agency (DARPA), he oversaw $200 million and 300 researchers from 20 companies, 16 universities, six national labs and seven government organizations as they forged ahead to make microchip-scale gyroscopes. For his extraordinary contribution to defense technology, Shkel was awarded the Office of the Secretary of Defense Medal for Exceptional Public Service in 2013. He is now the associate dean of research and innovation at the UC Irvine Samueli School of Engineering.

The wine glass-like structure is made of fused quartz.

What was so revolutionary about Shkel’s idea? Picture this: It takes about three months of manufacturing, polishing and manual assembly of 96 parts to create a single high precision gyroscope - a process that costs a staggering one million dollars for a single extreme-quality device. The engineering craft is one that only a few companies in the world are skilled to do. His lab invented glassblowing technology that can create thousands of “small wine glasses” simultaneously by simply putting a specially prepared stack of wafers in a furnace at 1,500 to 1,700 C. “It’s like making muffins,” Shkel said, “we have specialized ovens, and wine glasses pop up like muffins with very little human involvement.”

It is extremely efficient because thousands of wineglass structures can be made instantly as they form and organize themselves organically and symmetrically. The researchers create air cavities inside wafers and the air trapped between wafers expands as the glass starts softening, becoming almost like liquid at such high temperatures. The combination of glass softening and a pressure increase inside the cavity does the magic of forming three dimensional micro-structures. When the shaped glass is pulled out from the furnace and cooled, the lab releases, metalizes and interfaces them with electrodes to complete the product.

The wine glass-like structure, made of fused quartz, is the heart of hemispherical resonance gyroscopes that have applications for defense, medicine, consumer electronics, transportation vehicles and much more. Over a dozen of Shkel’s inventions have been licensed by industry and are used for advanced braking systems in SUVs, autonomous driving, navigation of UAVs, gaming, stabilizing images on camera phones and more.

Shkel’s groundbreaking work has given him 43 issued U.S. patents, making his MicroSystems Lab a global leader in chip-scale gyroscopes and inertial measurement units (IMU). The processes he invented have achieved a mechanical quality factor in the millions. This means that once stimulated, the resonator will oscillate on its own back-and-forth well over a million times before it loses its energy, which is a record for micro-scale devices. This quality factor is a key characteristic for precision measurement of rotations and reduction of drift in rotation measurements.

The Korean conglomerate Hanwha recently invested $3 million in MicroSystems Lab’s research to construct a prototype that would cut the cost to produce a high precision hemispherical resonance gyroscope to just a few hundred dollars. “If we succeed, this would give the sensor in our cell phones the navigation capability of those on Boeing 747s,” Shkel said. Hanwha wants to use the technology for highly autonomous vehicles of the future. The Hanwha investment is the largest single industry award UCI has received to advance a faculty invention and demonstrates the tremendous value Shkel’s research brings to the market.

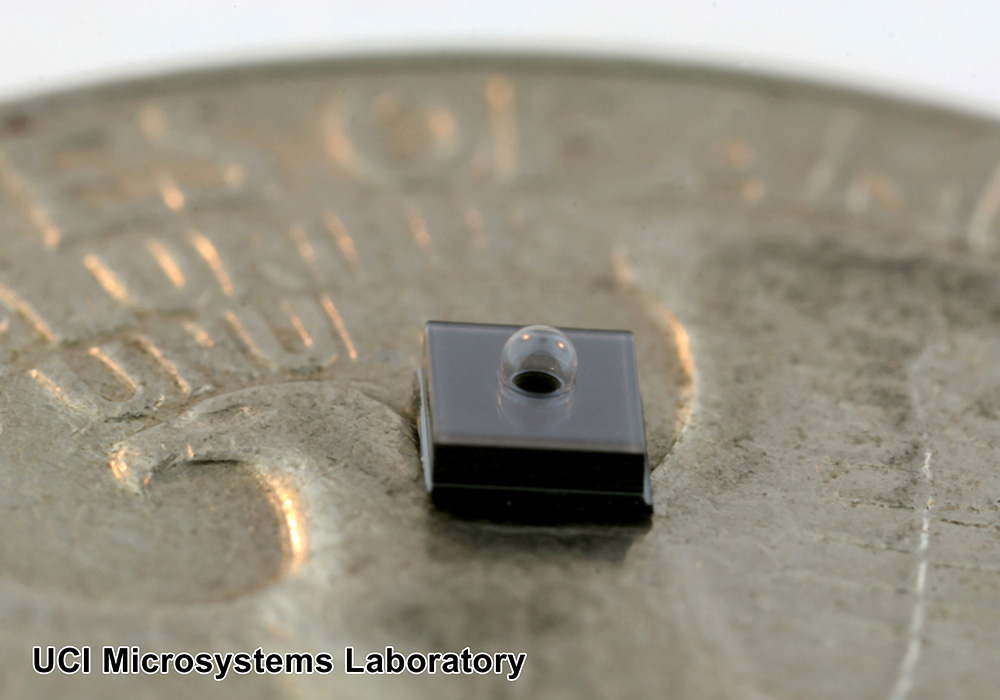

Diced silicon chip with a side length of 2mm on a U.S. quarter. The chip contains a blown glass sphere with a diameter of less than 1mm.

In a project called NEVERLOST, Shkel is working on putting mini gyroscopes and accelerometers in the soles of shoes worn by first responders so their whereabouts can be known at all times. It will go where current GPS technology cannot – indoors and in covered outdoor environments. His lab is also developing a location-based service that provides path guidance for emergency responders to help them arrive at a goal destination, such as an emergency exit from a building. This project was awarded nearly $1.4 million from the National Institute of Standard and Technology Public Safety Communication Research division.

Shkel’s biggest dream is to make microchips that can restore the inner ear’s vestibular system, which provides a person’s sense of balance and spatial orientation. Currently, there’s no known cure for those who lose their sense of balance and it’s the main reason the elderly fall and hurt themselves. Future microchips could potentially be implanted to prevent those injuries.

Other biomedical applications include developing lower limb prosthetics that are a more natural fit to the patient. AI can collect motion data and make personal adjustments to the device via these mini-inertial sensors.

The applications are endless as the lab works to perfect its mini gyroscope technology. “Every time I see a glass shop, I start thinking, ‘What can I do next?” said Shkel, the man who revolutionized gyroscopes with a glance at a glass blower.

- Natalie Tso