New Discovery Could Impact Design of Magnesium Alloys

Jan. 21, 2021 - Research underway in the lab of Tim Rupert, associate professor of materials science and engineering, has uncovered an anomaly in magnesium alloys, super light materials that show great promise for energy efficiency. In a paper published last month in Physical Review Letters, a high-impact physics journal, Rupert and first author Yang Hu, a recent doctoral graduate, detail these variances, which involve so-called twin defects.

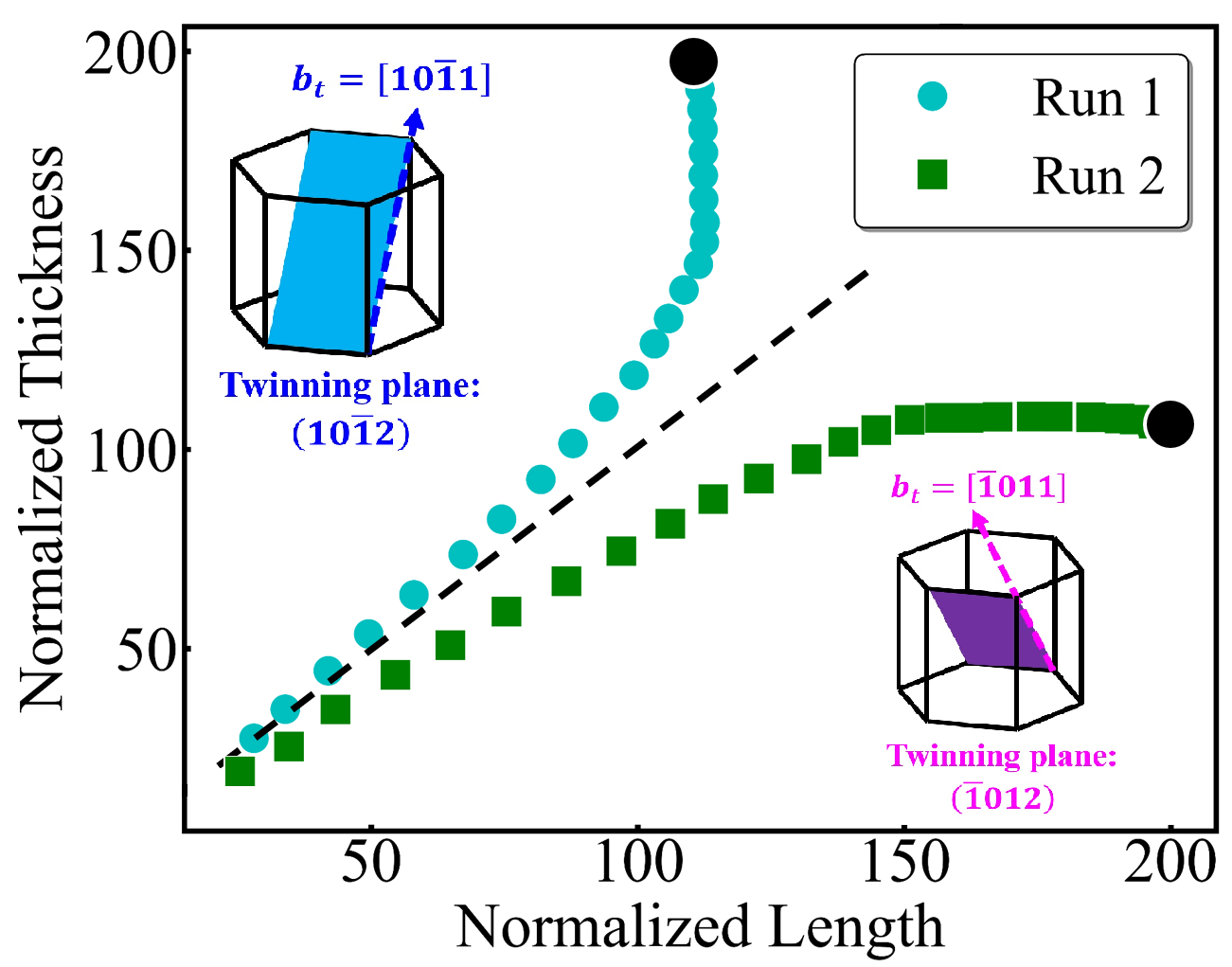

Twin defects are crystals within the material that are mirror images of other crystals, and they grow during the deformation of magnesium and magnesium alloys. In the majority of materials, Rupert says, these twins grow in a deterministic fashion, meaning that scientists can predict how they will behave if they know all of the local conditions, including what defects there are, what stresses are applied and the sample’s temperature, for example. But in certain magnesium alloys, growth of these twin defects is stochastic – there is some element of chance involved. This discovery can help materials scientists design promising new microstructures.

Twin defects (along with twin boundaries, the unique interfaces that bound the special crystal and appear as a mirror plane inside of the material) can exist naturally or be created artificially by modifying how the material is processed. Magnesium has a hexagonal close-packed crystal structure, making the twins more important than in most other load-bearing materials, which are typically cubic in structure.

“Our discovery opens the way for modifying the twin content and its topology in new and exciting ways,” Rupert said, “and allows us to better control the material’s properties.”

The project, a collaboration with UC Santa Barbara and UC Davis researchers, seeks to create interconnected networks of twins called twin meshes, which can allow engineers to make magnesium less brittle and more ductile (deformable without losing toughness). Since magnesium is 33% lighter than aluminum and 75% lighter than steel, Rupert said, this could open the door to extremely light structural materials that could be used to make highly fuel-efficient vehicles, for example.

“This research describes some fundamental deformation mechanisms of twins in magnesium alloys that have not been reported before,” said Hu. “We demonstrate that by introducing a certain amount of alloying elements into pure magnesium, the growth direction of twins becomes stochastic even when other conditions such as stress and temperature are the same. This contributes to filling a gap in the complete understanding of twinning in these alloys, and also sheds light on the emerging technique of strengthening and toughening magnesium alloys through 3D twin meshes.”

– Anna Lynn Spitzer