Samueli School Producing Face Shields for Health Care Workers

April 6, 2020 - When word came from the UC Irvine medical community that health care workers would run short of personal protective equipment during the COVID-19 pandemic, professors and staff at the Samueli School of Engineering did what engineers do. They started making stuff.

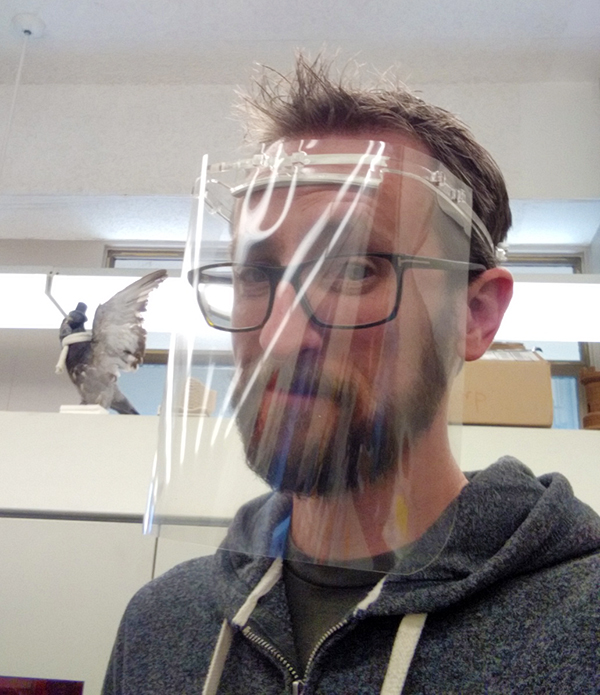

Ben Dolan, technical director at the school’s Institute of Design and Manufacturing Innovation (IDMI), started reviewing the many plans on the internet for 3D-printed face shields. Dolan runs the engineering school’s rapid prototyping facilities Rapidtech and FABworks, both well equipped with 3D printers, laser cutters and other advanced manufacturing technologies. After testing a few, he quickly determined that using 3D printers to make the shields would take far too much time − 30 minutes to an hour or more for each frame. Collaborating with Jesse Jackson, associate professor of studio art in the Claire Trevor School of the Arts, Dolan designed an acrylic frame that could be created with nearly any laser cutter in three to five minutes.

Focusing on easily available materials and getting the fit right for comfort and protection, Dolan and Jackson went through a couple of design iterations in consultation with Linda Dicky, director of quality & patient safety/epidemiology infection control, and Susan Tiso, clinical professor and director at the Sue & Bill Gross School of Nursing. The result is the UCI shield, comprised of an acrylic frame, a flat transparent film that covers the face, an elastic band from the local fabric shop, padded weather stripping for the forehead and a couple small zip ties.

The shields are designed for COVID-19 protection only. And while they could be reused after either being wiped down with alcohol or left unused for three days, they’re meant to be disposable. Dolan and Tyler Schuldt, an IDMI lab technician, are able to produce 72 shields simultaneously on four laser cutters. “We just wanted to respond to the serious demand for these shields in the quickest way possible,” Dolan said.

“We are delighted to be able to provide our equipment and the technical expertise of our excellent staff in response to this unprecedented emergency,” said Lorenzo Valdevit, professor of materials science and engineering and IDMI director. “We look forward to continuing to engage with all campus units to make sure essential products are designed, prototyped, fabricated and delivered to the personnel in need.”

UCI Beall Applied Innovation staff are assisting with final assembly and delivery to the medical center, as well as using their laser cutters to add to the count. “At Beall Applied Innovation, we are connecting crucial resources across campus, industry and the entrepreneurial ecosystem, and this capability is helping us to combat COVID-19 issues. It has been wonderful to see so many departments work together for the good of our front-line medical staff at the UCI Medical Center,” said Carolyn Stephens, Applied Innovation’s Enterprise Collaboration Group managing director.

To date, they have well over 1,000 shields ready to go and are approaching that volume per day. In addition, Dolan and Jackson have fine-tuned a frame design that can be printed on the type of 3D printers used by hobbyists in their homes. “As an alternative to the laser cut version, this frame could be printed by those in the community who have smaller 3D printers and want to contribute to the effort,” said Dolan.

– Lori Brandt