The Strongest Size in Metals

Feb. 10, 2020 - It’s an age-old dilemma for scientists and engineers: how does one make the strongest possible metal without sacrificing ductility? Ductility, defined as a material’s ability to undergo deformation without breaking, usually has an inverse relationship with strength. Generally, the stronger a material, the less likely it is to be ductile, and vice versa.

Penghui Cao, Samueli School assistant professor of mechanical and aerospace engineering, believes there is a way to achieve improved synergy between strength and ductility by tailoring grain size distribution. In a paper published online in Nano Letters, Cao discusses a new approach that utilizes a gradient, or grain size distribution, in the size of the grains that comprise copper.

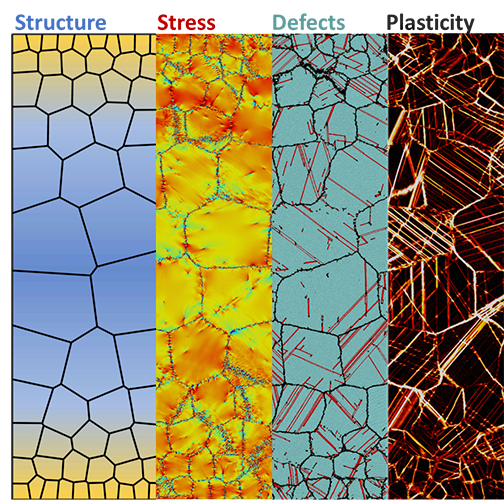

Specifically, Cao conducted computer simulations using different sizes of copper nanograins. By controlling the gradient – putting smaller grains closer to the boundaries and larger grains toward the center of the sample – Cao found a way to tailor the material to control the plastic processes governing strength and ductility.

In a typical polycrystalline metal with a uniform grain size, the material gets stronger as the grains get smaller – up to a point. At that specific point, decreasing the grain size causes the material to start softening, because the smaller grains begin sliding around and over each other.

“What is the critical grain size that can give you the maximum strength? That’s a fundamental question for the scientific community,” Cao says.

By varying grain sizes in a specific way, a process he calls tailoring the gradient, Cao was able to “tune” the strongest size, achieving maximum strength. “If you increase the gradient – the rate at which the grain size increases from small to large – you could get better mechanical performance,” he says. The ultimate payoff is ultra-small grains, which in homogenous structures begin sliding, but in these gradient structures, attain deformability characteristics that lead to a high degree of strength without sacrificing ductility. “You can tune to the desired mechanical property by tailoring the distribution of the grain size,” he says.

While the research is based on a simulation of micrometer-sized copper samples, Cao believes this approach can become a building block for different materials in varying sizes. “Gradient-structured systems, such as trees and bones, are ubiquitous in nature,” Cao says. “Now, our study has revealed that we can use these mechanisms to improve mechanical performance in gradient metals.”

- Anna Lynn Spitzer