Feb. 15, 2018 - “We’re surgeons!” said Darwin Salgado, a second-year biomedical engineering (BME) student, who had just finished suturing his 3-D printed heart valve into a pig heart. Salgado was one of 30 undergraduates participating in the hands-on project provided by the Biomedical Engineering Society (BMES) at UC Irvine.

Feb. 15, 2018 - “We’re surgeons!” said Darwin Salgado, a second-year biomedical engineering (BME) student, who had just finished suturing his 3-D printed heart valve into a pig heart. Salgado was one of 30 undergraduates participating in the hands-on project provided by the Biomedical Engineering Society (BMES) at UC Irvine.

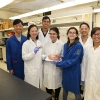

In teams of two, the undergraduates suited up with lab jackets, goggles and gloves, and spent two hours completing the task designed to give them an understanding of heart anatomy and current cardiovascular diseases. UCI BMES board members designed the two-quarter program.

“We were really excited to be able to offer this experience to students. It’s something they can put on their resumes to help them get internships and jobs,” said Andrew Chang, UCI BMES president. The student society used the project to recruit members this year, more than doubling last year’s 49 members to 112.

During fall quarter, the students researched the appropriate dimensions of a heart valve, learned to model their valves in SolidWorks, a computer-aided design and modeling program, and used a 3-D printer to create and refine prototype heart valves. Then in winter quarter, they learned about the structure and flow of blood through the heart, the current state of prominent heart diseases as well as methods of treatments.

The project’s culmination was the opportunity to work with a mammalian heart in a lab in Engineering Tower. The students, who all had been required to complete safety training prior to entering the lab, used a surgical scalpel and scissors to cut out the aortic valve and replaced it with the plastic valve that they had modeled. They also further dissected the heart to see the atrium and ventricular regions.

Two biomedical engineering graduate student researchers – David Li and Ziwei Zhong – were on hand to assist. “They did pretty well,” said Zhong of the undergraduates. “They were all able to suture a valve in.”

The project was the brainchild of Cynthia Hernandez, activities coordinator for BMES. Her brother, a chemical engineering and materials science major, had participated in the Chem-E Car project, and Hernandez thought there should be a similar hands-on experience for BME students. Heart valves are a big industry, especially in Orange County, home to two large medical device companies – Medtronic and Edwards Life Sciences – that most students hope to work for one day.

“I thought it would be cool to give students the experience to do something with the resources on campus and have an opportunity to work with heart valves,” said Hernandez, a second year student. She joined the BMES board last spring so she could propose the project. It was funded with grants from the Samueli School Engineering Student Council.

Salgado, who is interested in working with medical devices, said he learned a lot about the heart’s four chambers, adding that the night’s most difficult part was trying not to break the plastic valve while sewing it in. “It was hard to maneuver,” he said, “but I enjoyed myself; it was a fun project.”

– Lori Brandt