EECS Paper Showcased in Journal of Micromechanics and Microengineering Highlights

Associate Professor Andrei Shkel and Ph.D. Student Jesper Eklund author paper chosen among 2007 highlights

Andrei Shkel, Ph.D., associate professor of mechanical and aerospace engineering, electrical engineering and computer science, and biomedical engineering, and fifth-year electrical engineering Ph.D. student, Jesper Eklund, authored a paper that was chosen to be included in the Journal of Micromechanics and Microengineering (JMM) 2007 highlights, a showcase of the top contributions to the field published in 2007.

JMM covers all aspects of micro-electro-mechanical structures, devices and systems, as well as micromechanics and micromechatronics. The journal emphasizes the link between fabrication technologies and their capacity to create innovative devices. Shkel and Eklund’s paper, titled “Single-mask fabrication of high-G piezoresistive accelerometers with extended temperature range,” was selected for the highlights list by the JMM editorial board, who chose papers that were the most accessed online and considered to be of the highest quality. Shkel and Eklund’s paper was downloaded more than 300 times during 2007, and will be available free online for everyone to view until Dec. 31, 2008. Their research was conducted with partial support from VIP Sensors, Inc., and UC Discovery, and has a patent pending.

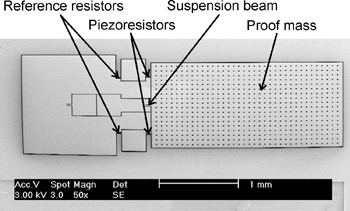

Their paper outlines a fabrication process for micro-accelerometers, designed primarily to measure large accelerations. Possible applications of these devices include automotive crash testing, airbag deployment systems, and munitions testing. The presented accelerometers are based on a piezoresistive sensing principle, or the change in resistance when a conductive material is stretched or compressed.

However, contrary to conventional piezoresistive accelerometers, which typically require at least five separate fabrication steps, Eklund and Shkel’s fabrication technique allows the accelerometers to be created in a single step, thus reducing the complexity and cost of the sensors. This is achieved by utilizing silicon-on-insulator (SOI) wafers with a specific resistivity.

The insulating buried oxide layer in these wafers allows the piezoresistive elements of the accelerometers to be defined and insulated from each other, and from the bulk silicon, without the pn-junctions normally required to insulate piezoresistors in conventional sensors. In addition to reducing the complexity of the fabrication, the operational temperature range is also extended compared to other piezoresistive accelerometers, making these sensors suitable for usage in high-temperature environments, such as engines and industrial machinery.

Shkel is interested in the design and advanced control of micro-electro-mechanical systems (MEMS) for biomedical, communication and inertial navigation applications. His research focuses on the development of high-precision, micro-machined gyroscopes; MEMS-enhanced optical systems, tools and prosthetic appliances; and, the integration of electro-mechanical and machine-information systems. He received B.S. and M.S. degrees in applied mechanics from Moscow State University, and M.S. and Ph.D. degrees in mechanical engineering from the University of Wisconsin at Madison.

As a student in Shkel’s lab, Eklund’s research projects include the nuclear magnetic resonance (NMR) gyroscope, piezoresistive accelerometer for high-G applications, and optical accelerometer based on fabry-perot interferometry. Eklund is pursuing a Ph.D. degree in electrical and computer engineering, and holds an M.S. degree in electrical and computer engineering from UC Irvine.

Scanning electron micrograph of an SOI-based piezoresistive accelerometer, fabricated in a single fabrication step.